Cavitation and Impingement |

Cavitation occurs when a fluid's operational pressure drops below it's vapor pressure causing gas pockets and bubbles to form and collapse. This can occur in what can be a rather explosive and dramatic fashion. In fact, this can actually produce steam at the suction of a pump in a matter of minutes. When a process fluid is supposed to be water in the 20-35°C range, this is entirely unacceptable. Additionally, this condition can form an airlock, which prevents any incoming fluid from offering cooling effects, further exacerbating the problem. The locations where this is most likely to occur, such as:

At the suction of a pump, especially if operating near the net positive suction head required (NPSHR)

At the discharge of a valve or regulator, especially when operating in a near-closed position

At other geometry-affected flow areas such as pipe elbows and expansions

Also, by processes incurring sudden expansion, which can lead to dramatic pressure drops

This form of corrosion will eat out the volutes and impellers of centrifugal pumps with ultrapure water as the fluid. It will eat valve seats. It will contribute to other forms of erosion corrosion, such as found in elbows and tees. Cavitation should be designed out by reducing hydrodynamic pressure gradients and designing to avoid pressure drops below the vapor pressure of the liquid and air ingress. The use of resilient coatings and cathodic protection can also be considered as supplementary control methods.

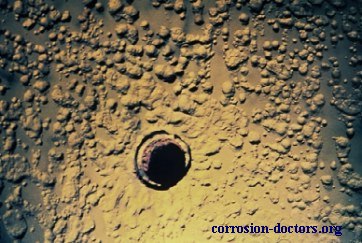

Cavitation corrosion of a deaerator

Impingement attack is related to cavitation damage, and has been defined as ‘localized erosion-corrosion caused by turbulence or impinging flow.’ Entrained air bubbles tend to accelerate this action, as do suspended solids. This type of corrosion occurs in pumps, valves, orifices, on `heat-exchanger tubes, and at elbows and tees in pipelines.

Impingement corrosion usually produces a pattern of localized attack with directional features. The pits or grooves tend to be undercut on the side away from the source of flow, in the same way that a sandy river bank at a bend in the river is undercut by the oncoming water.

When a liquid is flowing over a surface (e.g. in a pipe), there is usually a critical velocity below which impingement does not occur and above which it increases rapidly. Impingement attack first received attention due to the poor behavior of some copper alloys in seawater.

In practice, impingement and cavitation may occur together, and the resulting damage can be the result of both. Impingement may damage a protective oxide film and cause corrosion, or it may mechanically wear away the surface film to produce a deep groove.

| (previous) | Page 19 of 23 | (next) |