Charles Martin Hall (1863–1914)

Charles Martin Hall was born December 6, 1863 in Thompson, Ohio. He was son

of Rev. Heman Bassett Hall and Sophronia H. Brooks Hall. In 1873 the Hall family

moved to Oberlin, Ohio, where Charles Martin Hall took his preparatory work

in Oberlin High School. His high school education was supplemented by one year

in the Oberlin Academy including lessons in the Conservatory of Music. He enrolled

in Oberlin College in 1880, and graduated with a bachelor of arts degree in

1885.

Charles Martin Hall was born December 6, 1863 in Thompson, Ohio. He was son

of Rev. Heman Bassett Hall and Sophronia H. Brooks Hall. In 1873 the Hall family

moved to Oberlin, Ohio, where Charles Martin Hall took his preparatory work

in Oberlin High School. His high school education was supplemented by one year

in the Oberlin Academy including lessons in the Conservatory of Music. He enrolled

in Oberlin College in 1880, and graduated with a bachelor of arts degree in

1885.

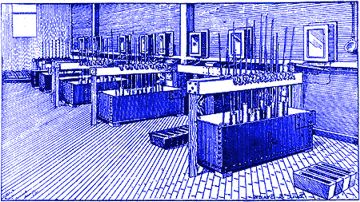

Eight months after graduating from Oberlin College, Charles Martin Hall invented an inexpensive method for the production of aluminum. On February 23, 1886 in the woodshed behind his family's home, Charles Martin Hall produced globules of aluminum metal by the electrolysis of aluminum oxide dissolved in a cryolite-aluminum fluoride mixture and repeated this experiment the next day for his sister Julia to witness. This achievement was the culmination of several years of intensive work on this problem. Hall was granted patent #400,655 for his process (1889). In the same year, Hall found a financial backer in Alfred E. Hunt, and the two of them founded the Pittsburgh Reduction Company (later ALCOA).

Up to that time, pure aluminum was considered a precious metal, used only in fine jewelry; now, aluminum began to be used in industry. Most importantly, aluminum allowed automobiles and airplanes to be lighter, more fuel-efficient, more rust-resistant, and less expensive. Not only did Hall have to devise a method for winning aluminum metal, but he also had to fabricate most of his apparatus and prepare his chemicals. In his early experiments he tried to adapt the high temperature carbon reduction methods that were used in the metallurgy of iron and other metals of intermediate chemical activity. He also tried to reduce the aluminum in cryolite with sodium metal. In subsequent experiments Hall, working in Jewett's laboratory in Cabinet Hall, showed that the electrolysis of aluminum fluoride in water gave only aluminum hydroxide. They understood that electrolysis provided more powerful reduction conditions than did chemical methods. Today, it is well known that hydrogen in water is more easily reduced than is aluminum ion.

In 1907 the Pittsburgh Reduction Company was renamed the Aluminum Company of America, later shortened to ALCOA. In 1890 he became its vice president. By 1914 his process had brought the cost of aluminum from twelve dollars per pound down to 18 cents a pound.

Hall was a generous benefactor of his college, bequeathing Oberlin more than $5,000,000.These interests were manifested in his collection of oriental rugs and porcelain, and enjoyment of music. The success of ALCOA following the Cowles settlement allowed Hall to return to his interest in music and art. Hall also remained active in research and development, a passion which for him never ended. He filed several new patents for improvements in the production of aluminum, including one registered four years after his death. In 1911 he was awarded the prestigious Perkin Medal for outstanding achievement in applied chemistry.

Connect with us

Contact us today