|

|

|

|

|

|

|

|

|

|

|

|

Brine Corrosion

The ASTM standard G78 describes a procedure for the evaluation of the susceptibility of a metallic material to crevice corrosion in specific environments. Technically, this procedure works like a charm when noble or corrosion resistant materials are tested in relatively corrosive environments. The multiple crevice assemblies (MCAs) used in this test favor the formation of an even more aggressive chemistry at the interface between the grooves machined in the inert material and the piece of metal being tested and on which the MCAs are pressed with known force.

During a recent discussion thread on the NACE International discussion list the question was raised about the possibility of crevice formation of steel components exposed to natural seawater. The flurry of messages that followed the initial question by Dr. Bob Cottis (> 60 messages in approximately one week) clearly indicates that this topic is at the frontier of our knowledge in this apparent simple matter. It should be noted that no clear consensus was reached during that debate.

The question was simple: will there be crevice corrosion attack on these washers?

| The picture on the right shows the largest washer (3.8 cm diameter) used in these experiments after one month in the 3% NaCl solution with normal aeration an no agitation. After brushing off the top side of the carbon steel washer to remove loose corrosion products we could see general pitting corrosion attack everywhere except near the Teflon of the MCA that was pressed on the steel, where the attack seemed to be more localized. |  |

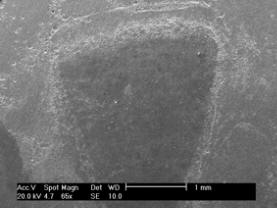

| A close-up view with a scanning electron microscope revealed the shallow groove made by the corrosion attack of the steel while the area underneath the Teflon material and further away from the MCA still had the striations marks made before exposure by the final steel wool polish. |  |

| The bottom side of the washer was covered by magnetite everywhere except in a couple of spots of the washer where the washer was touching the glass beaker and around the MCA where the corroded grooves were also present. The area near the MCA was therefore the anodic area while the larger area was the cathode that produced the magnetite, a reduced form of corrosion products. |  |

An analysis of the other washers revealed similar but less accentuated features, i.e. corroded grooves on the contour of the MCAs, the grooves being more important on the washers exposed to the saline environment than on those exposed to tap water. The corroded grooves also seemed to be more important on larger washers than on the smaller ones.

Obviously we did not produce a typical crevice attack during these experiments. There are many reasons for this. One being that the environment was quite benign and the exposure period relatively short. As we are planning follow-up experiments we would like your views and opinions on this matter.

Please send your suggestions to our .

Simple experiments to illustrate the theory:

Corrosion current, Galvanic coupling, Rust preventive testing