|

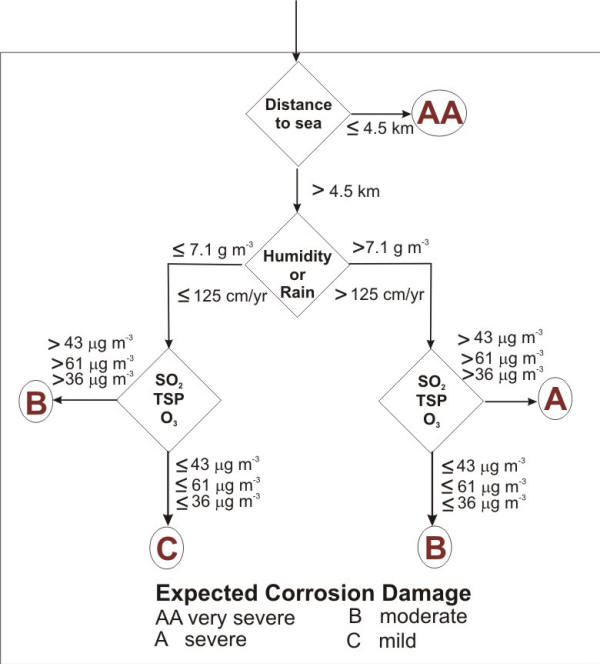

An environmental corrosivity scale, based on atmospheric parameters, has been developed over the years for the maintenance management of structural aircraft systems. A corrosion damage algorithm (CDA) was proposed as a guide for anticipating the extent of corrosion damage and planning maintenance operations. This classification scheme was developed primarily for uncoated aluminum, steel, titanium and magnesium alloys exposed to the external atmosphere at ground level. The section of the CDA algorithm presented in the following Figure considers distance to salt water, leading either to the very severe AA rating for close distance to seashore or a consideration of moisture factors.

The PACER LIME algorithm for determining the corrosion severity for a given location.

Following the moisture factors, pollutant concentrations are compared with values of Working Environmental Corrosion Standards (WECS). The WECS values were adopted from the 50th percentile median of a study aimed at determining ranges of environmental parameters in the U.S. and represent “average of averages”. For example, a severe A rating would be given if any of the three pollutants considered in this scheme, i.e. sulfur dioxide, total suspended particles and ozone levels, would exceed the WECS values in combination with a high moisture factor.

The environmental corrosivity, predicted from the CDA algorithm, of six marine air bases has been compared to the actual corrosion maintenance effort expended at each base. Considering the simplicity of the algorithms and simplifying assumptions in obtaining relevant environmental and maintenance data the correlation obtained was considered to be reasonable. Further validation of the CDA algorithm approach was sought by comparison of the predicted corrosivity data to actual coupon exposure results and a good agreement was reported between the algorithm rankings and available experimental data. However, subsequent attempts to enhance the PACER LIME algorithm by using the results obtained from broad based corrosion testing programs have failed to provide enough differentiation between moderately corrosive environments and were not considered in the final classification scheme adopted.

In order to remedy some of the deficiencies in this scheme Battelle has been tasked to monitor the atmospheric corrosivity of Air Force and other sites worldwide. The database describing the relative corrosive severity levels of different locations and actual corrosion rates of a variety of metals has now grown to more than 100 sites worldwide. The metals included in that study are three aluminum alloys (A92024, A96061, and A97075), copper, silver and steel.

The data are collected for metals directly exposed to the outdoor environment in a standard sample mounting configuration and test package. A typical plastic test rack with its metallic coupons is shown in the following Figure besides a CLIMAT coupon exposed at the KSC beach corrosion test site.

Metal coupons in a plastic test rack exposed at the Kennedy Space Center beach corrosion test site besides a CLIMAT coupon. (Courtesy of Battelle Institute)

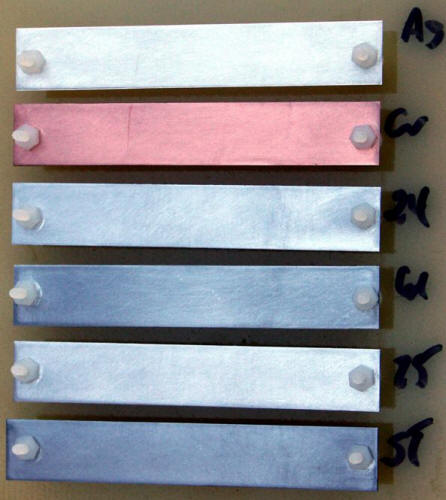

The following Figure shows a close-up view of the coupons before exposure.

Metal coupons before exposure to the environment. (Courtesy of Battelle Institute)

Once exposed to the environment for a given period of time the corroded metal strips such as shown in the following Figure would be sent back to the laboratory for mass loss measurements following standard methods and further analysis.

Metal coupons before exposure to the environment after a three month exposure in a rural environment. (Courtesy of Battelle Institute)

The International Organization for Standardization (ISO) has implemented a worldwide atmospheric exposure program known as ISO CORRAG. This program includes exposure of steel, copper, zinc, and aluminum for 1, 2, 4, and 8 years at sites located in 51 sites in 14 nations in order to generate the necessary data to produce a classification system for predicting atmospheric corrosivity from commonly available weather data. The standard was obviously not intended for extreme service atmospheres such as those within chemical or metallurgical processing facilities or where there is direct contact with salt spray.

The program consisted of six one-year exposures of flat panels (100 x 150 x 2 mm) and helix specimens beginning every six months for three years. Triplicate specimens were used for each exposure. The metals selected were a low carbon steel from a single supplier and commercially pure zinc, copper, and aluminum. These nonferrous metals were obtained from local sources in each of the participating nations. The program was initiated in 1986 and officially closed in 1998. At the conclusion of each exposure, the specimens were retrieved and sent to the laboratory that had done the initial weighing for cleaning and evaluation. Mass loss values were obtained and converted to corrosion thickness loss values . Based on these data, a simple classification scheme of five corrosivity classes was established for each metal.

Experience from applying the ISO classification system has shown, however, that certain observations need further clarification. Substantial corrosion has also been measured on specimens exposed at temperatures well below 0°C, which is in direct contradiction to the ISO criterion. It is proposed on the basis of these results, that the TOW in these environments be estimated as the length of time that relative humidity exceeds 50% and the ambient temperature exceeds –10°C.

he ISO 9223 standard indicates that there should be no corrosion at temperature below 0oC. Independent researchers have however proposed to lower the minimum temperature stated in the standard to lower values in order to account for the actual corrosion observed in Nordic climates. Provide an explanation for the observed corrosion at temperature below the freezing point.

The north-eastern U.S. and Canada corrosivity map shown on the previous page is a simple and efficient way to communicate the general features of atmospheric corrosivity. Similar corrosivity maps have been created from data available in the literature. A list of the maps is available here.

| (previous) | Page 6 of 8 | (next) |